Downloads

Click here to download the full quick installation guide. Or continue reading below.

You can also find additional installation videos here.

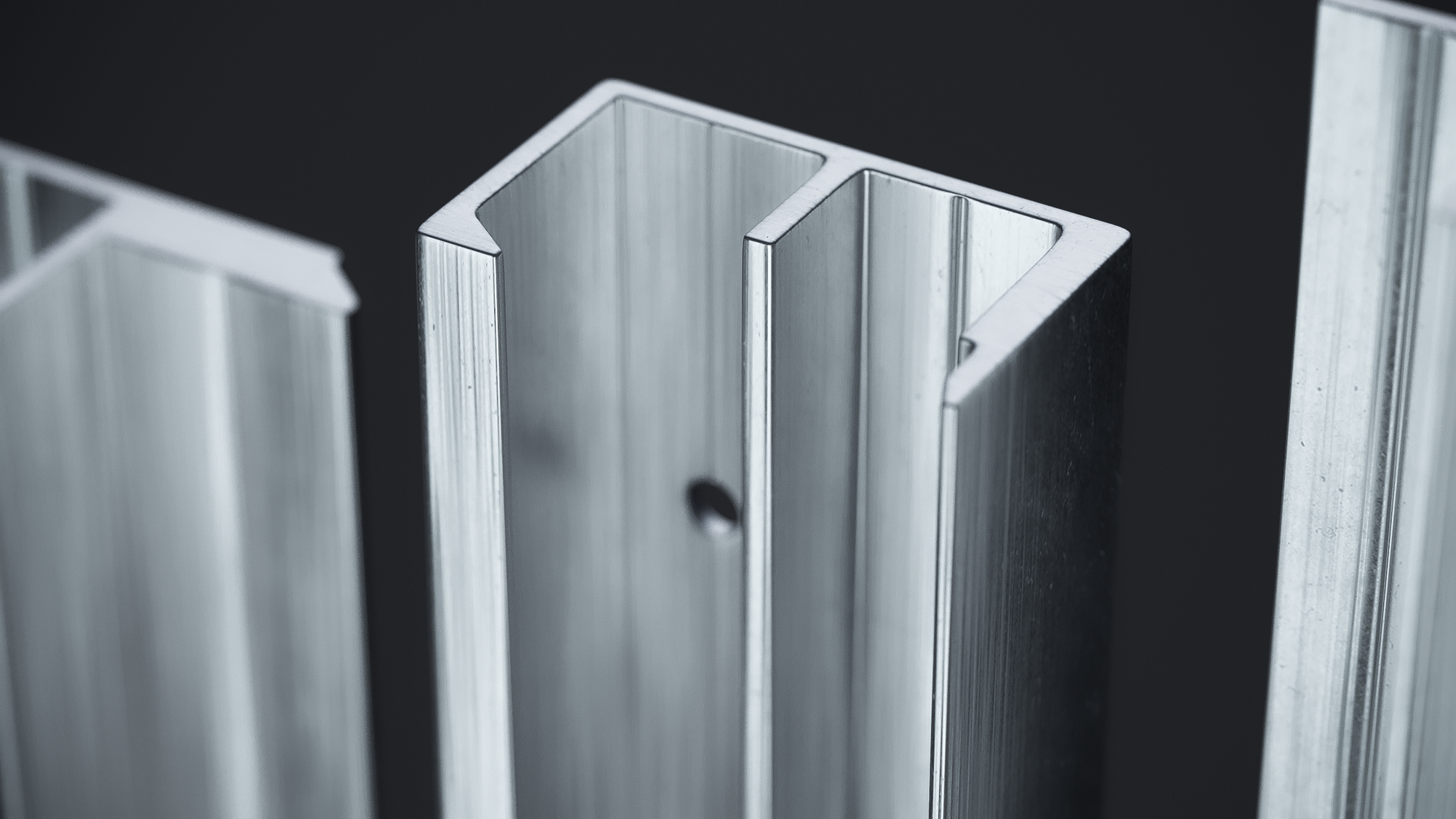

Step 1 - Create Channel

There are 3 methods to create the channel: Hand chisel, router, or, for the professionals, using a dado blade/table saw. The most common method is to router out the back of your shelf to make the room for the female bracket. It is important to note that the bottom of the bracket is .80mm longer than the top. We recommend having the the top of the bracket .40mm (a fingernail) recessed from the shelf & a .40mm overhang for the bottom. This is to allow for the bracket to slightly embed itself into the drywall to prevent any unwanted rocking once installed.

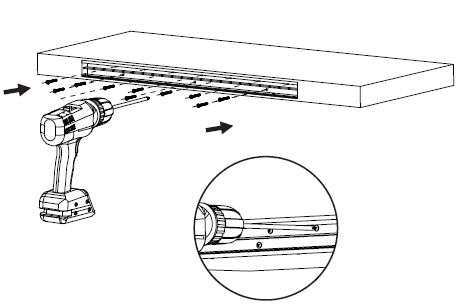

Step 2 - Attach Female Bracket to Shelf

Use the 1 1/4” pan head screws to secure the bracket to your shelf. Please use 1 screw per hole.

Step 3 - Drill Set Screw Holes

Option 1: You will need to drill & tap the holes in the bottom of the shelf to accommodate the threaded set screws for the bracket that we will be using to secure the two components together towards the end of the installation process.

Option 2: You either can use epoxy glue only to secure both brackets together later in the installation or combine both methods. Epoxy is a more permanent installation.

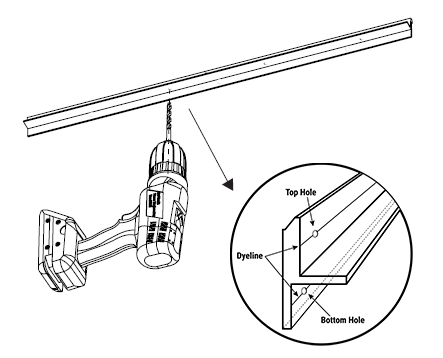

Step 4 - Preparing the Male Bracket

You will need to drill the necessary holes into the male bracket. Please use the 3/16” tapper bit. The reason we don’t pre-drill the bracket is due to the vast variety in stud separation in each individual case. It is recommended to find a minimum of 2 studs. Mark your studs on the bracket & ensure you drill your holes centered on the provided top & bottom dyelines on the bracket.

Step 5 - Attach the Male Bracket to the Wall

When attaching the male bracket to the wall, please use #8 - 2½” long panhead screws. Start by drilling one screw using the top hole but not tightening all the way. Then use a level, make sure the bracket is levelled before drilling your second screw into the other stud. Tighten the screw (but not so much the bracket bends) then go back and tighten the first one. Then screw in the bottom screws in each stud. It’s important to make sure you do not over-tighten. One “click” or hand-tight is plenty. If the screws are too tight, it will cause the bracket to bend, compromising the integrity of the Hovr Bracket System.

Step 6 - Combine Both Brackets Together

Tilt your shelf downward at a 15° angle to begin engaging the 2 brackets together. Hook the upper part of your female bracket onto the upper part of the male bracket. Once you feel the grooves begin to interlock, pull the shelf down into place and connect the two components.

In the case the brackets are not fully engaged initially, apply 2-3 solid taps at the back of the shelf where the brackets sit. This should cause the brackets to snap fully into place, leaving a level shelf.

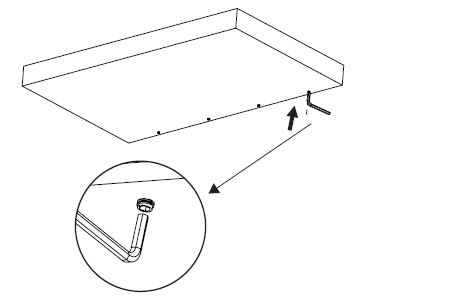

Step 7 - Secure Brackets Together

Insert the set screws into the pre-drilled & tapped holes. Screw them in by hand until they are finger tight, and then finish securing them with the provided Allen key. The tighter the better. Alternatively, there is the method of using Epoxy glue instead of set screws. This will reduce the load the shelf can handle. Combining both methods together gives the strongest results. You can find out more at hovrsolutions.com/learn.

Hovr Strong Solutions (the “Company”) makes no representation or warranty as to the suitability of its products for any particular purpose, use, or installation, nor does it make any suggestion as to the method by which any of its products should be installed. The Company makes no suggestion nor shall be taken to provide any instruction on any tools, equipment or machinery used in any way in connection with its products, and strongly suggests that the consumer consult with and abide by any user manuals or instructions provided by the manufacturer of any utilized tools, equipment or machinery and at any time they are used, that such use is conducted in a safe and lawful manner. It is the responsibility of the consumer to ensure the correct usage of any tools, equipment, or machinery utilized at any time in connection with any Company products.

The information provided in any video by the Company is not intended as, and shall not be understood or construed as, advice or instruction in the operation of any tools, equipment, or machinery for use in connection with any Company products. Neither the Company, nor any of its employees, agents or anyone else for whom it is at law responsible shall be held liable or responsible for any loss, damage, or injury stemming from the use of any tool, equipment, or machinery utilized by a consumer in connection with any Company products.